Through our technology partner GIW industries, the following press release was issued:

GIW Industries, Inc., a company involved in the design, manufacture and application of heavy duty centrifugal slurry pumps, has announced the successful design and installation of a unique underwater pump system for a Chinese dredging contractor.

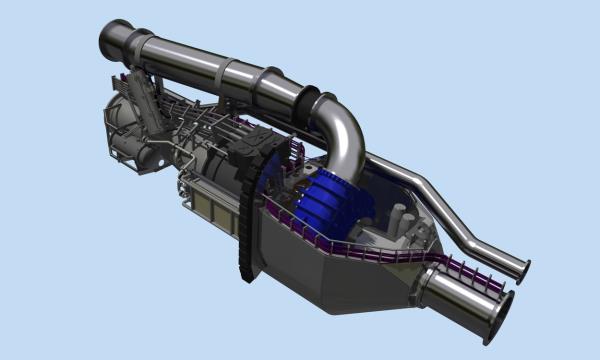

This equipment package consists of a GIW® Minerals LHD pump directly mounted onto a 4500 kW submersible electric motor and housed in a carrier arm attached to the drag arm of a trailing suction hopper dredger.

The upgrade allows the dredger to operate efficiently at depths up to 100 meters.

The 58″ impeller and 4500 kW/6000 hp motor significantly decrease the filling time of the 15,000 cubic meter hopper when operating at depths in excess of 35 meters, thereby increasing the overall efficiency of the dredger.

For this project HollandMT has provided basic and detailed design of the complete underwater pump unit, including frame, structural analyses, piping, auxiliary systems and routing of e-cables.

For this project HollandMT also provided supervisory assembly services at the shipyard in China.

|